- Button Badge Maker

- Brand

- Button Size

- 1.73 In / 44 Mm (9)

- 2.28 Inch / 58mm (3)

- 2.5cm - 7.5 Cm (4)

- 2.5cm / 0.98 (20)

- 25mm / 0.98in (7)

- 3.2 Cm (1.26 Inch) (4)

- 3.2cm / 1.25 (3)

- 3.2cm / 1.26 (19)

- 3.7 Cm (1.46 Inch) (4)

- 4.4 Cm (1.73 Inch) (10)

- 44mm / 1.75 Inch (3)

- 44mm(1.73 Inch) (4)

- 5.8 Cm (2.28 Inch) (20)

- 5.8 Cm (2.3 Inch) (5)

- 5.8cm / 2.28 (45)

- 5.8cm / 2.28\ (52)

- 58mm (2.28 Inch) (20)

- 7.5 Cm (3 Inch) (24)

- 75mm / 2.95 (5)

- 75mm / 3in (8)

- Other (2995)

- Die Size

- 0.98, 1.26 (2)

- 2.12 In / 54 Mm (9)

- 2.5cm - 7.5 Cm (4)

- 2.5cm / 0.98 (21)

- 25 Mm (1 Inch) (2)

- 25mm / 58mm (17)

- 3.2 Cm (1.26 Inch) (4)

- 3.2cm / 1.26 (23)

- 3.7 Cm (1.46 Inch) (4)

- 4.4 Cm (1.73 Inch) (11)

- 5.8 Cm (2.28 Inch) (22)

- 5.8 Cm (2.3 Inch) (5)

- 5.8cm / 2.28 (45)

- 5.8cm / 2.28\ (52)

- 54mm(2.12inch) (4)

- 58 Mm (2-1 / 4 Inch) (2)

- 58mm (2.28 Inch) (19)

- 7.5 Cm (3 Inch) (24)

- 75mm / 2.95 (5)

- Other (2989)

- Handle Length

- Origin

- Ships From

1+1.25+2.25IN 3Size Badge Button Maker Badge Press Machine 400pcs Circle Cutter

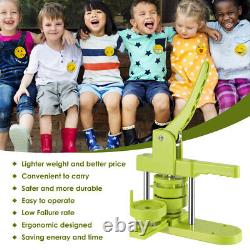

1+1.25+2.25IN 3Size Badge Button Maker Badge Press Machine 400pcs Circle Cutter. 1 inch(25mm), 1.25 inch(32mm), 2.25 inch(58mm). Comes with large, medium, and mini size molds for 400 button badges. Pay Attention To distinguish the small and medium molds, do not install the wrong mold.

400 Pin-back Button Badge Supplies? Kits include 400 sets pin buttons.

300 plastic button badges(100pcs for each size) &100pcs metal button(1inch). The included circle cutters make it possible to make your own pieces of paper in the desired size. Makes a badge in less than 15 seconds after installation. Please watch the using video or manual in detail before use. For the 1.25'' and 2.25'' metal back buttons you do need put a washer first. We have included extra 1.25'' and 2.25'' washers for you to use when making metal back badges. The pin maker adopts the appearance of high-strength engineering plastic, the body and the mold are integrated, light weight and easy to operate.A top-rotating die not only improves efficiency and accuracy, but also facilitates better positioning. You will take less 15 seconds to make a badge when installed correctly.

Can be used for photo storage, ornament decoration, wedding name tags, classroom crafting, etc. We look forward to more creative design showcases from you! You Can Make 400 Pinback Button Badges. What can you do with buttons? Reward and motivate students, or as a member badge for a wedding party (or any group). Use the Photo Button to showcase an athlete you support or a favorite. You can also show your voice for publicity in some public occasions, and it can also be used as a decoration to add interest. The size of the button made: 1'', 1.25'', 2.25'. The entire button is made of 5 pieces (Clasp Pin, Metal or Plastic Back, Metal Shell, Paper Graphic, Clear Plastic Cover). Why we choose plastic backs? We opted for a more durable PP plastic back instead as the metal will rust when exposed to moisture over time.After you are proficient, you can make a badge in about 10 seconds. You can make a total of 400 badges. 1''# 200pcs, 1.25''# 100pcs, 2.25''#100pcs. These molds are suitable for badge making materials marked 1", 1.25" and 2.25 on the market. 1 x Button Maker Machine.

1+1.25+2.25 inch Molds. 3 pcs Circle Cutter & 3 metal pins & 4 screws & 2pcs L wrench & 2 washers. Installing the molds are important steps.

Please do not install the mold in the wrong orientation. In most cases, subsequent making failures are caused by mold installation errors, so please follow the instructions and videos to install. Show You How to Make a Button Badge.When crimping the metal cover, paper and plastic clear covering, the pegs on the top mold do not go into the holes (as shown in step 4). When crimping the pinback button with top pieces, the pegs need go into the holes(as shown in step 7). Also, In this step, you need to use a little force to pull the handle to the end Some reviews said "It won't crimp the paper and plastic clear covering around the metal backing".

The failure was due to a lack of force during the second crimp. TROUBLEINGSHOOTING---Button Making Problems - Solved Common Crimping Problems. Your first thought is usually that the machine is broken or the parts are defective but it is extremely rare that either of these are the case. Question 1: "Why are my buttons coming apart" or Why is there plastic clear coverin. Not tucked in on the side of my button? 1: Make sure there are no problems with the installation. If something goes wrong with the installation, all subsequent steps will fail.2: One of the most common causes is that your paper is too thick or too thin. We recommend using 24-28 pound copier paper. Your graphic has to be cut exact and even. It should not be bigger than the plastic clear covering and the edges need to be nice and even. 4: You need to push the handle down with a bit of force in the last press.

It is best to hold the handle tightly with your hands when pressing for the last time, so that the upper and lower molds can be tightly combined with each other. 5: The top mold may become loose after a long time of use. If the mold is loose, that's maybe the cause you failed pressing. Tighten with an L wrench before installing the upper mold if it needs(Do not over tighten, make sure the upper die can rotate properly).

Don't forget to put the metal pin that holds the sliding mold fixing. Only put one piece of paper and plastic clear covering at a time, too thick material can cause jamming and seal failure. Since papers or plastic clear covering are easy to stick together, you may not notice how many layers are there when putting.

In the first crimping, the pegs on the top die cannot go into the hole, but in the second crimping, it is needed. Question 2:Why is my metal cap stuck inside the mold and won't seal after the last press? Please use an intact metal cover, not deformed. Do not reuse failed metal cover.

When the pinback button is put into the mold, the buttons are upside down. The correct placement is with the pin side down. If the metal cap stuck inside the top mold, press again to let it off.

If you pay means you agree with the postal service. If you have any question, feel free to send us a message and we will reply you within 24 hours. Due to the difference of time zone, sometimes the reply will be delayed with 24 hours(excluding weekend & holiday). Enjoy your visiting and shopping here. This item is in the category "Crafts\Multi-Purpose Craft Supplies\Crafting Tools\Badge/ Button Makers".

The seller is "imdkdi" and is located in this country: US. This item can be shipped to United States.- Brand: Mryitcal

- Handmade: Yes